Sia Xeros leaned forward, brandishing a small net over an open tank. “I can’t catch him,” she said, peering at the three translucent shrimp scuttling around the bottom of the tank. “He doesn’t like being caught.” A momentary battle ensued between prawn and woman: “Oh yeah, hide with the other ones. That’s a good idea.” She bent further over the tank, net at the ready. “They’ve kind of been babied,” she explained.

It only took a few more moments for the net to emerge victorious, holding an abnormally large shrimp, ten inches long, that climbed to the rim of the net with multiple legs wiggling. This was Pepe, the mascot of The Salty Prawn, Chicago’s one and only sustainable saltwater shrimp farm. “If you hear something different, let me know,” said Xeros, the co-founder of The Salty Prawn along with Kate Purvis.

Although a couple of other farms raise shrimp in Indiana, The Salty Prawn operates in the city itself, in the basement of a former industrial meatpacking facility in Back of the Yards. Now a vertical farm and sustainable food business incubator known as The Plant, the building is home to nine other tenants besides The Salty Prawn, ranging from Arize Kombucha to the Great American Cheese Collection.

While the for-profit tenants focus on their businesses in the space given in The Plant, the nonprofit organization Plant Chicago does research and development work both for its tenants and sustainable food production and energy conservation in general. Both Xeros and Purvis worked in this vein for The Plant before setting up shop in the basement a year ago.

Farms like The Salty Prawn’s, Xeros and Purvis had noticed, were “usually in the middle of nowhere,” like those shrimp farms in Indiana.

“Why can’t we start it here?” Xeros recalled thinking. “We have the market, we have the background. Why not try it?”

“It” is a “biofloc” saltwater system contained in three large, circular tanks, each fourteen or fifteen feet in diameter, in a 1400-square-foot space in a humid room shared with The Plant’s aquaponics farm. These open-air vats, which carry about 8,000 shrimp each, aren’t too photogenic; each is filled to a height of two-and-a-half feet with orange-brown water, which Xeros euphemistically describes as “different-colored.” That’s how the biofloc technology works: Xeros and Purvis cultivate harmless protein-filled bacteria (the source of the color) for the shrimp to eat. The shrimp then excrete toxic ammonia and nitrate, which the bacteria clean from the system, controlling the water quality. The shrimp help out too—when they molt, the shells they shed disintegrate and bring calcium back into the water. They never get rid of the water in the vats, Xeros said, and the biofloc system requires far less feed.

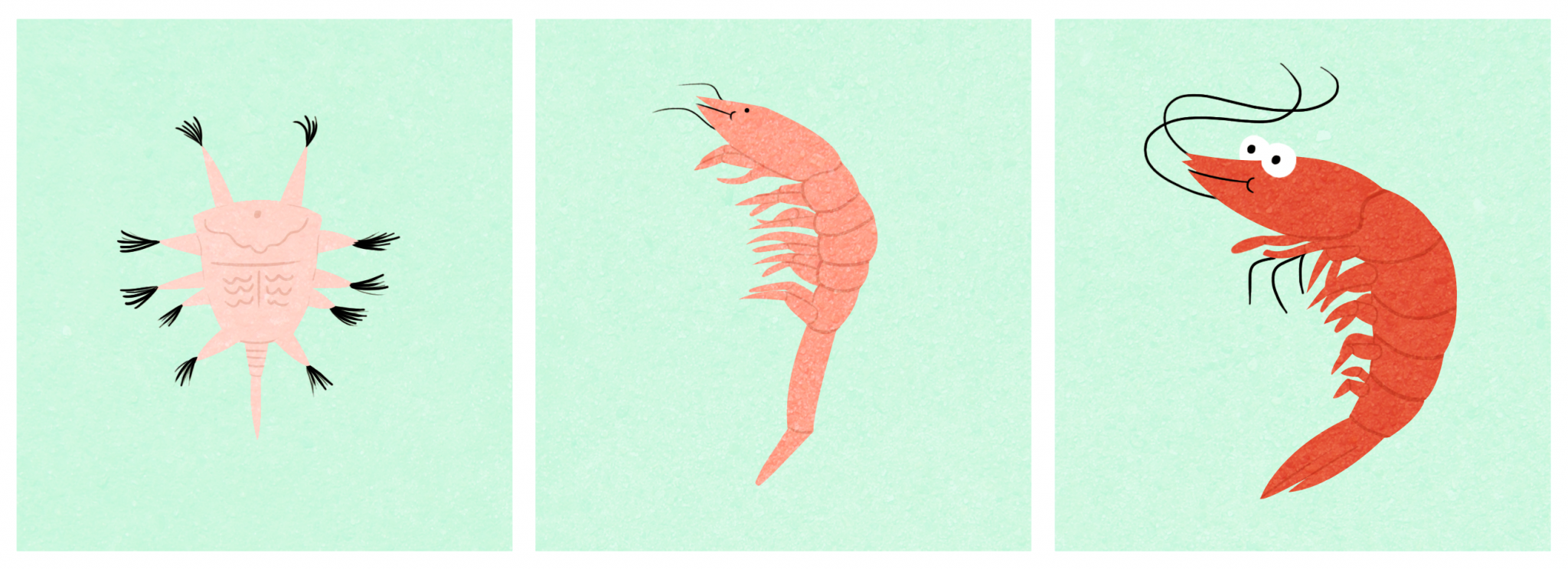

With the system set in place, taking care of the shrimp is “not simple,” Xeros said, but fairly routine: their shrimp come from a pathogen-free hatchery in Florida and are about eleven days old when they arrive, at which point they look, if anything, like grains of dirt, but jumpier. While one of the large tanks is being cultivated for them, these baby shrimp live in a small nursery tank for about a month. Splitting up the weekdays, either Xeros or Purvis tests the water chemistry of the large tanks every morning, and every day they scrape the bottoms of the tanks to make sure there’s no leftover feed. Once or twice a week they weigh each batch of shrimp to determine feed size. Much of their time is devoted to research.

“We do a lot of research in general,” Xeros said. “This is not a normal system.”

Of course, with the rest of their time they sell shrimp. Their harvests are usually small, consisting of five to twenty pounds of shrimp to process and prepare for delivery. The Salty Prawn doesn’t have a large enough supply for retail, though Xeros said they plan on expanding, and have been in talks with wholesalers.

“We’re still in startup mode, proving the concept and making sure we know how to grow shrimp,” she said.

For now, their dealings within The Plant and the local area are enough. Nana, an organic restaurant in Bridgeport, is a regular client, and The Salty Prawn shrimp never last long at The Plant’s Monthly Markets—in March they sold five pounds in half an hour, harvested another three pounds, and were clean out of that too an hour before the market ended. Once The Plant establishes a retail shop, shrimp will be available there as well. Just a couple weeks ago the company made their first delivery as a member of Hooked on Fish, a sustainable seafood delivery service.

In keeping with The Plant’s goal of fostering interaction between its tenants, Xeros said they eventually planned to sell to other tenants within The Plant, like Pleasant House Bakery. They’re helping out The Plant itself, too: The Salty Prawn’s shrimp water is used in an algae bioreactor upstairs, where tubes filled with greenish water clutter the windows.

“It’s a nice little network of connecting people,” Xeros said.

Given these business choices, not to mention the close affiliation with a sustainability-focused nonprofit, it’s no surprise The Salty Prawn isn’t a typical for-profit company—it’s a benefit corporation, a type of for-profit that prioritizes social and environmental impact and has been around in Illinois since just 2013.

“Profit is not necessarily the only thing we use to base our [business] decisions off of,” Xeros said. “We have social, economic, environmental responsibility.”

Sustainable loop systems, benefit corporation responsibilities, partnerships with The Plant—what’s the result? How do the shrimp taste? Bluntly, immediately, confidently, Xeros replied: “Different.”

The Salty Prawn delivers shrimp within four hours of harvest, and restaurants use their shrimp within forty-eight hours of delivery, so it’s never frozen and fishy-tasting.

“We’re told it’s a lot fresher tasting,” Xeros said, and sweeter than usual. “As soon as it’s frozen, it loses that sweet taste.”

However they taste, one thing’s for certain: Pepe the mascot won’t join his fresh, unfrozen brethren. Pepe and the other two shrimp he shares the tank with are from The Salty Prawn’s first ever harvest, and they’re a good display for the people who come through The Plant on weekly public tours.

“They’re from our first batch,” Xeros said, watching Pepe cling to her net, “so we’re kind of nostalgic.”